Value Added Marketing Sheep 3

This is the last in our Value Added Marketing sheep series. We are going to talk about value added marketing wool products.

This is one of my favorite topics, and I tend to ramble about wool. I am an accomplished hand spinner, and wool hoarder, as my husband often tells me. I love wool. I love that there are so many different natural colors, textures, grades and so much you can do with it.

As I said before I am a spinner so I have been value adding wool for a very long time. I also have felted many projects, and on top of that have sold fleeces and fiber for many years. I knit so I know what I like, and have also tried to weave but do not have the patience that takes.

So let’s start from the beginning before I start just rambling.

As we discussed in the first article in this series Value Added Marketing Sheep 1 wool sheep are bred for their fleeces. Some are bred for ultra-fine garment wool like Merino and Rambouillet sheep. Some are bred for their fleece length like Lincoln or Leicester. Some sheep are bred for no wool, these are often called hair sheep like Barbados, or Katahdins.

First we are going to talk about the fine wool sheep and value adding to this wonderfully soft, naturally wicking, warm fiber. You may remember that scratchy wool blanket your grandma had, wool is not naturally scratchy. Those blankets are commercially made and the cleaning process crushes a lot of the debris in the wool and it is spun into the fiber. This is important to you because it will be very important to keep your sheep as free of hay, grass and other debris as you can. This can mean anything from making sure your hay is put out in small feeders on the ground then turning the sheep in, to making sure you clean all the burrs and weeds that may get in the wool out of your pastures.

Wool has been one of nature’s wonders to man for centuries. Sheep were shorn or combed and this warm fiber was made into clothing for warmth. Today we have many, many different fibers that are made into clothing most are man-made. The most used natural fibers are, cotton, flax, and wool. Wool is the warmest of the three and has been used for shelter and clothing since early biblical times.

Since we are talking about value adding you need to find out what your breed of sheep’s wool is most used for. If you don’t know you need to have your wool graded and find out if it is course or fine.

Fine wool fleeces have lots of grease. This grease is called lanolin which you will need to wash out of the fleece very carefully. You can save the lanolin when you wash your fleeces to make wonderful natural hand cream. However to have enough to make a product you will need many fleeces. You can purchase lanolin and make a product that will market very well with your other wool products if you so desire, but I digress.

The steps to value adding your fleeces are below. You will need to decide how many steps you want to take. You have value added if you do more than just selling it right after shearing.

- Shearing – Getting a good professional shearer is very important. Second cuts shorten the fibers and are your enemy.

- Sorting – It is important no matter what type of sheep or wool you have that you take the time to pull all the tags (large poop balls) off of the fleece, and sort the finer yearling fleeces from the older courser ewe fleeces.

- Skirting /Grading – First you will need to pull off the wool around the back end, and the hairy part on the legs. If you used a good shearer they will have probably already pulled the belly off. These pieces are useable but are of a different grade, and most likely to have debris in it. Then you will need to break the fleeces into groups of at least two. The finer micron fleeces and the courser fleeces. I generally sort into three groups but this is your choice. If you only have 3 sheep and they are similar in fleece then you can skip this step.

- Washing – I would recommend that you send your fleece to a professional carding operation to have your fleeced washed if you have never worked with fiber. However if you want to save yourself some money, and you have the knowledge or are willing to do some learning then you can do the first wash to get out much of the grease and dirt before you send it away to have it professionally carded. If you want to card it yourself you will need to wash it at least twice if it is fine wool. CAUTION learn about washing wool first you can felt it and ruin the whole lot if you don’t know what you are doing.

- Carding- You can send your fleeces to a professional carder, or purchase a drum carder and card your own wool. If you spin yourself you can even spin the wool in the grease. However I really would recommend that you wash it and card it first to be sure you are getting a good clean yarn. The carding process takes the washed fleece and fluffs it up and combs it so that it is going the same direction. This aids in making sure your yarn is soft and even.

- Blending- One hundred percent wool is wonderful and a supple yarn without blending with any other fibers. However if you want to add some mylar, or blend with alpaca, silk, or some other fiber for a project, then this is a good place to blend. You can also blend after you dye your fiber if you choose to dye it, or just keep it natural anything is alright it is your product.

- Dyeing—I love to dye fiber. I have done natural plant made dyes, I have used commercial wool dyes, and I have used kool-aid to dye wool. All of these work very well. I would however not recommend using RIT Dye as it is not as dye fast as wool dye. Follow the directions and make sure you use the same temperature water through every process.

- Spinning – This is my favorite part. I can lose myself during a spinning project. I have several fleeces right now and am very excited to get started cleaning and spinning them. Depending how busy I am sometimes I have professionally carded roving and other times I use my own carder. If you are spinning to weave the yarn you will spin with courser fiber, and less twist. If you are spinning fine wool you will need more twist, and a finer thread. This is something that you can learn on your own, or sign up for our Sheep to Garment workshop this summer.

- Knitting/Weaving/Crocheting– I am not a weaver. I however have worked at a loom during a class many years ago. I enjoyed the process very much, but I really enjoy knitting so I personally went that direction for my yarns. I also crochet. If you have never used handspun yarn you are in for a treat. It is the most wonderful yarn, and is scrumptious to work with.

So all of the steps above are all value adding to the price of your fleece. Now let us take an average fleece of about 8 lbs., and see how much we can make it worth.

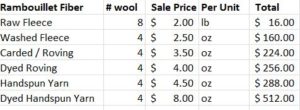

Using a Rambouillet fleece below I will give you an example of value added prices from the web. These are only suggested, and your fleece prices will depend on several of the factors we talked about above. Example:

So you will need to figure how far you want to go with value adding. You also need to keep in mind the estimates above are constantly changing, and are the gross prices. No expenses, for cleaning, time or products were taken out of the prices received.

Hope this article will give you some ideas of how you can make sheep a part of your Small Farm. You can do many things to Value Add to your Sheep Program.